?What is bagasse

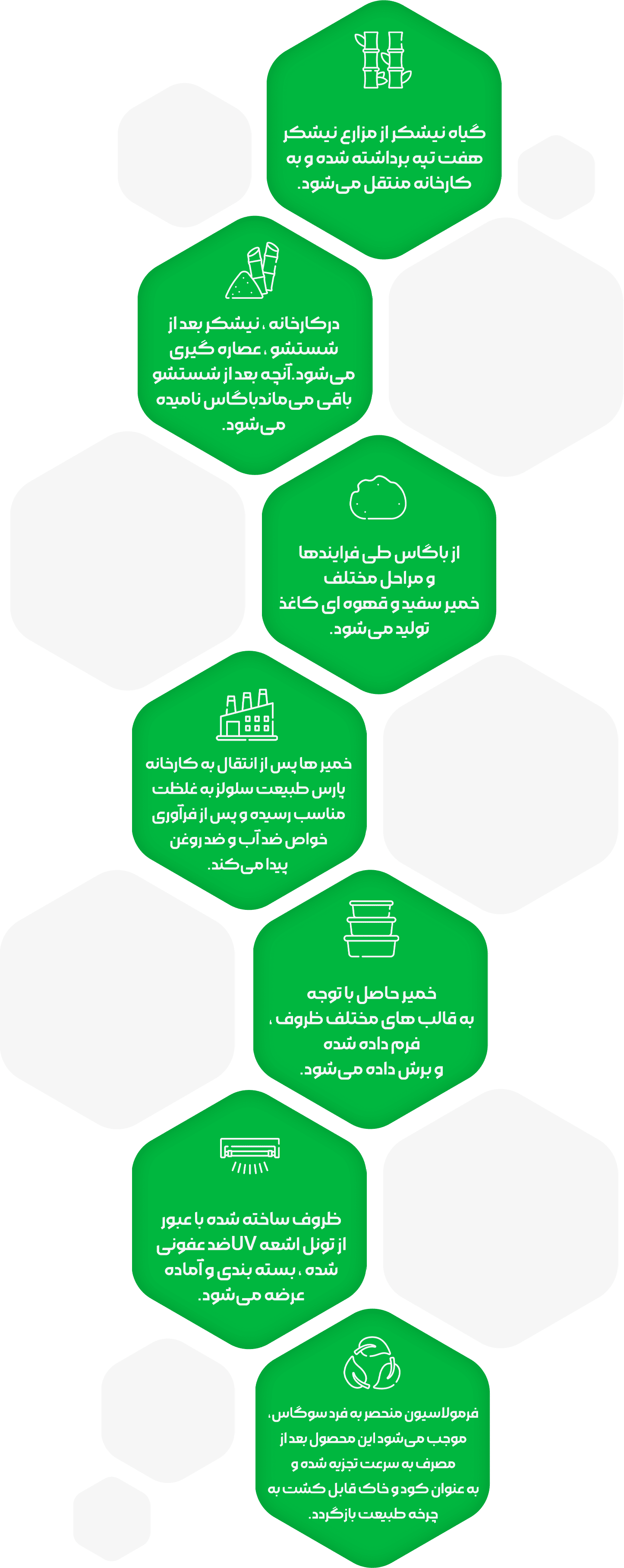

Bagasse is a by-product of the sugar production process of sugarcane. When the sugarcane stalks are crushed, a dry, papery substance called bagasse remains. Of course, there is a similar substance called agave bagasse, which is derived from the agave plant. Sugarcane bagasse is used in the production of paper and pulp, building materials and fuels. Fuel that is environmentally friendly and usable in the production of energy, heat and electricity

History of bagasse

The word bagasse is derived from the French word bagage meaning waste. For the first time, what remained of plant processing processes such as olive pressing, date kernels and grapes was called bagasse. But today it is called exclusively bagasse sugarcane. The main use of bagasse is in the paper industry. The method of using bagasse in paper production was first invented in a small laboratory called Clarence Birdsong in a sugar factory called Paramonga in Peru. With this promising discovery, the company bought an old paper mill in New Jersey. He sent Bagasse from Peru to test the reliability of the project on an industrial scale. This method was developed in 1937 and the first paper machines were designed in Germany in 1938. But bagasse paper was first produced commercially in 1950 in the form of newsprint by Noble & Company Machine Wood. This product was completely successful in front of 100 industrial representatives and 15 national officials. The economic significance of this discovery was even greater in countries that did not have easy access to wood fibers for paper production due to their climate. In 2015, the Paramunga Sugar Factory, which first developed the method, produced about 90,000 tonnes of bagasse paper.

Production, storage and properties of bagasse

Due to the fact that bagasse is a by-product of sugarcane, the amount of bagasse production in each country corresponds to the amount of sugarcane produced in it. Usually, out of every 10 tons of chopped sugarcane, three tons of wet bagasse are produced. Brazil and India are the largest producers of bagasse because sugarcane is grown in many parts of these countries. Produce products, be collected. The bagasse is then mixed with water, until the resulting mixture forms a paste and is prepared for further processes. The bagasse is stored in different forms and methods depending on its final use. Normally, bagasse is stored at the beginning of the process. For example, in the production of electricity, bagasse should be kept in a humid environment with gentle heating, so that the fibers are gradually dried, but in the production of paper and pulp, bagasse should be kept moist to remove the brain fibers. Help. Brain fibers, or 30Pith, make up 40% of bagasse, and their properties prevent paper production.

In general, dried bagasse is chemically composed of the following materials:

45 to 55% cellulose

20 to 25 percent hemicellulose

24 to 28% lignin

1 to 4% ash and 1% wax

Uses of bagasse

As mentioned earlier, bagasse is used as a wood substitute in many tropical and subtropical countries such as India, Argentina and Colombia. Bagasse pulp has the physical properties suitable for printing paper, newspapers, cardboard, plywood, particle board, Xanita board and even the production of furniture and biodegradable utensils. Bagasse can also be used in furfural production. A clear, colorless liquid used as a solvent in chemical products such as nylon. Bagasse is often used as a fuel source for the sugar factory itself. When bagasse burns in large quantities, it produces relatively good heat energy, which is enough to run a typical sugar factory. Bagasse is also used as a secondary fuel to generate electricity and sell it to the consumer grid. Much research is being done on the use of bagasse as a biofuel in renewable energy. Bagasse has the potential to be used as an environmentally friendly alternative to corn as a source of ethanol production. Because bagasse is rich in cellulose, cellulose ethanol can be produced in industrial and commercial quantities. But adapting this product to current ethanol production machinery and technologies requires further research. The high humidity of bagasse complicates the use of this product as a fuel. Bagasse mixed with mullein (sugar syrup) and enzymes are also used in the animal feed industry. And Australia is on the market

Stability

As mentioned earlier, sugarcane is a fast-growing renewable resource. Bagasse as a by-product of sugar production is also a resilient and stable product. There is no need to cut pressure trees on forest areas for further cultivation. Therefore, bagasse is a sustainable and environmentally friendly alternative to paper production that was previously produced from wood, with the least amount of energy wasted. All materials and products produced from bagasse are fully biodegradable and compostable. Suitable conditions can decompose in less than four weeks. Many restaurants have replaced used food containers and plastic products with containers and products made from bagasse. In fact, bagasse will revolutionize the ready-to-eat food industry, as it has the highest demand for disposable tableware on the market. Plates, bowls and napkins made of bagasse are a suitable, sustainable and extraordinary alternative to the needs of these industries. It is clear that bagasse is not only an effective and sustainable source but also one of the most reliable.